Metal Coping Systems

What Is Metal Coping?

Horizontal top surface of the wall is the most vulnerable point for water to penetrate. The effective way to waterproof this spot is to cap the wall with formed metal coping.

What Types of Metal Coping Can We Manufacture?

Bensalem Metal can offer several types of metal coping systems along with installation service if needed. It can be either sloped or level. Metal coping can be fabricated from various materials. These are the most common designs that we recommend. We can also fabricate other kinds if required by the project’s specifications. The forming process of metal coping is easily refined and there are almost no restrictions on shapes that can be created.

Please click on the links below to get detailed information on each individual system of metal roof coping. You will also find technical data sheets, order forms and other valuable information corresponding to each specific metal coping system.

|

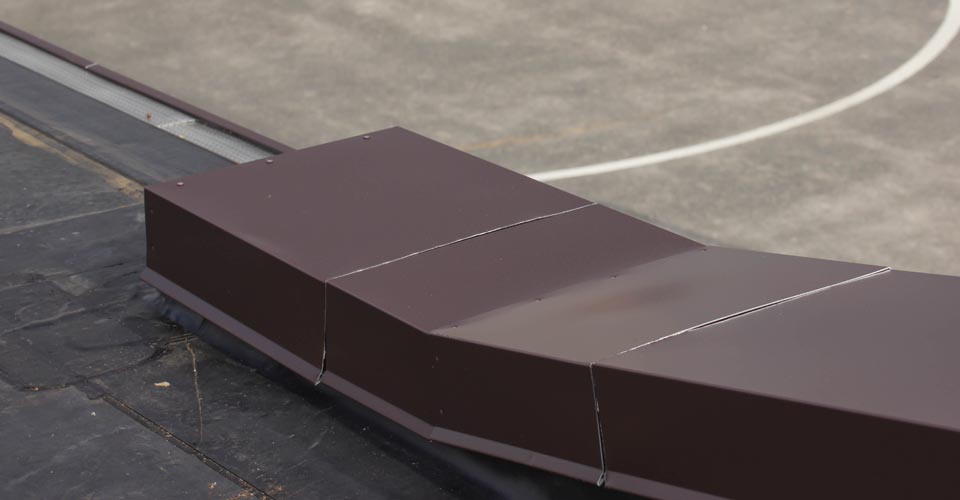

Simple System Sheet Metal CopingThis is the most common type of parapet wall metal coping. Continuous cleat is used on the side away from the roof. The interior side is fastened using screws with watertight washers. This system is very robust, easy to install and requires minimum of layout or preparations. This metal coping is the basic design recommended by SMACNA. Please click to learn more about Simple Sytem Metal Coping. |

Price starts from

$7/ LF |

|

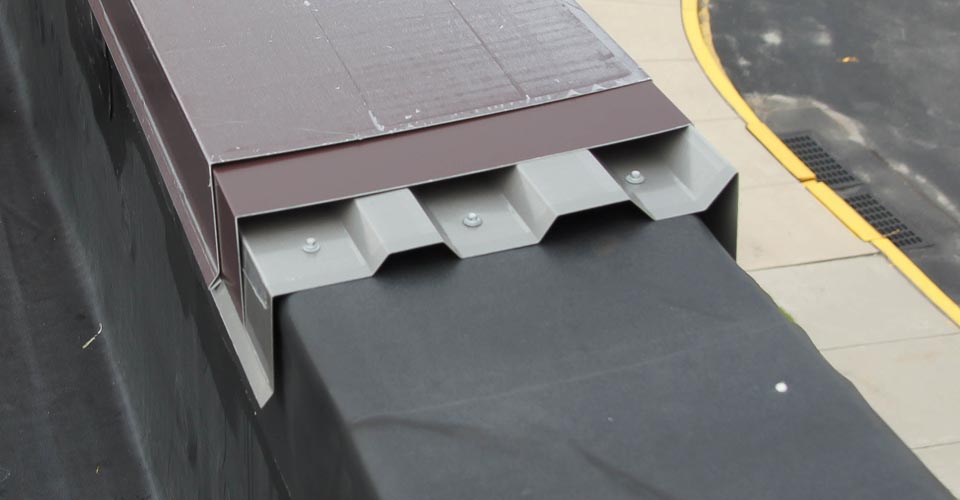

Snap Lock Roof CopingThis type of metal coping does not have continuous cleat on either side. Heavy gauge 12″ wide steel anchors are installed every 4 ft instead. The spring action of the metal cap itself locks the cover piece in place. This eliminates the necessity to use any exposed fasteners. The metal coping system is more aesthetically pleasing but might require some layout and installation skills. It is also prone to unlocking in areas where human traffic is present on roof. Please click to learn more about Snap Lock Roof Coping System. |

Price starts from

$9/ LF |

|

Continuous Cleat Spring Lock CopingHeavy gauge steel cleat can be installed continuously on both sides of parapet wall. Spring action of the front cleat locks the coping cap in place without the use of any exposed fasteners. The goal of this metal roof coping system is to match the criteria of having a “continuous cleat” without the necessity to use any exposed fasteners (opposing to Simple System option). However the installation process of this metal coping system can be challenging if the wood blocking widths varies along the length of the wall. Front and back cleats are not connected, so the installers have to be very accurate. Please click to learn more. |

Price starts from

$11/ LF |

What Materials Can We Use to Fabricate Metal Coping System?

Metal coping cap can be provided in several options. All aluminum and steel will come with industry standard Kynar 500 finish and will carry long term manufacturers warranty against discoloration. It will also have clear plastic protection film that will be removed after installation. Here is the list of most common metals used for coping systems fabrication:

| 1. Aluminum Coping |

|

| 2. Galvalume Steel Coping |

|

| 3. Natural Metals and Other |

|

| 4. Aluminum Composite Materials (ACM) |

|

What Affects The Price of Our Coping Systems?

Price starts as low as $7 and averages at $9.50 per LF.

Every project is different and all dimensions are unique without any price increase. Please contact us to get an accurate quotation.

Here are some factors that may influence the metal coping system price:

| 1. Material and it’s thickness. | Thinner metal sheets are cheaper than heavier gauges. However the dependence is not linear. Kynar paint finish affects the price of the flat stock significantly as well as the fabrication itself. Flat stock material price takes up only 50%-60% of final system. |

| 2. The required attachment system. | Simple System is in most cases cheaper than Snap Lock or Continuous Cleat System. This is mostly due to less complexity and variations during fabrication process. |

| 3. Parapet wall width and other coping cap dimensions. | The coping cap dimensions influence the amount of metal to be used. Common practice is to try to arrange the dimensions in order to have a material cut of either 24″ or even 16″. The standard metal sheet size is 48″ wide by 120″ long. So in order to minimize the waste it is appropriate to try to fabricate either two (24″ cut) or three (16″ cut) pieces of coping cap from single sheet. |

| 4. Amount of corners and other accessories. | While it is possible to miter metal coping in field it is really not recommended. It may cost even more and will not look like a finished system. Accessories fabricated in our facility are cut by a precise equipment first and than formed and connected. This makes them all uniform. Accessories are usually priced from $25 for a snap lock end cap up to $120 for complex Y-shaped miters. Most common 90 degrees outside and inside corners rarely exceed $50 in price. However having dozens of them on a project may result in a significant increase of price per LF of an overall wall length. |

| 5. The project’s size. | We do not charge any fixed setup fee and on bigger projects (1,000 LF and more) we can give a better price per LF. |

| 6. The project’s location. | 10 feet long coping pieces are heavy and take large volumes. Freight charges start to weigh in significantly if the destination is further than 350 miles away especially on smaller jobs. However on bigger projects our aggressive pricing will soften the shipping costs hit. All pickups are free and easily arranged. |

What Warranty Will Our Metal Coping Carry?

-

Metal manufacturer warranty.

Aluminum and steel sheets are delivered to us painted (Kynar 500/Hylar 5000) by metal manufacturer. The finish is not damaged during the fabrication process. Each final piece of metal coping cap will come with plastic protection film. The final product will carry manufacturer’s metal finish warranty against discolorations for up to 35 years.

-

Bensalem Metal fabricator warranty.

We are providing lifetime system warranty for commercial projects. Proper installation and inspection are required.

What Are The Lead Times?

Lead times for different metal coping systems may vary but normally do not exceed 7-10 business days. We are willing to expedite any order if it is required and if flat stock is readily available.

Where Do We Ship?

All other areas can still be served as we ship nationwide. The delivery will be done through common carriers.

For local customers pickups are easily arranged as well.

How Can We Further Help You Out?

- Our managers will be glad to help with any questions regarding different metal coping systems. They can provide all necessary samples, color charts and shop drawings for owner’s or architect’s approval.

- At a moderate fee or in most cases free of charge we will assist you with the takeoff on your project.

You can see more product pictures in the Gallery section of our website.